Solvent Spray Cleaners in Cylinders: A Reason to Replace AK-225 Aerosol

At the end of 2014, another industrial cleaning solution that produces toxic effects in humans and the environment began the phase out process for discontinuation of use on U.S. soil: AK225 — also known as Asahiklin. This means that many companies and organizations across the nation have already phased out — or are in the process of phasing out — AK-225 and the AK-225 derived solvent spray cleaners below that are used for the following applications.

- For precision cleaning: AK-225, HCFC-225ca, HCFC-225cb

- For defluxing: 225AES, 225T, and 225ATE

- As carrier or heat transfer fluid: HCFC-225ca, HCFC-225cb

- As a coolant: HCFC-225ca, HCFC-225cb

- For drying after alcohol azeotrope use: 225AES, 225T, and 225ATE

- For displacement drying: 225DH

- For vapor degreasing: AK-225

- For oxygen cleaning: 225G

- For aerosol applications: AK-225

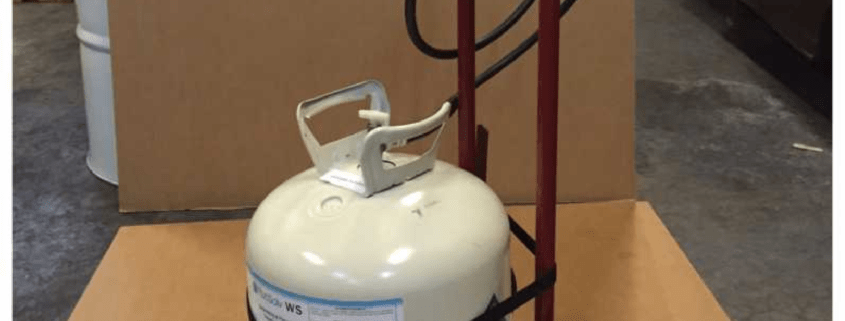

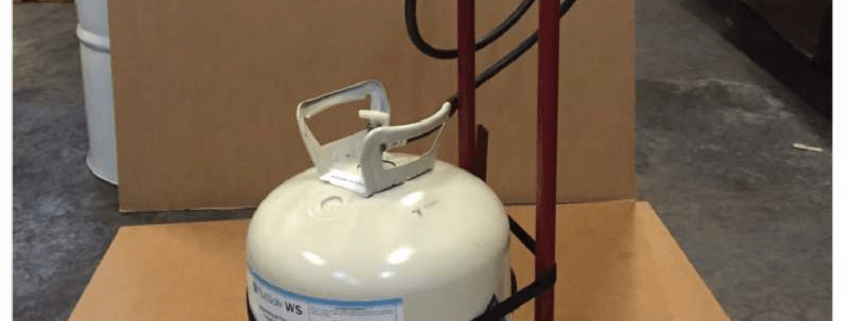

Users of AK-225 and associated solvent spray cleaners are government mandated to discontinue using the solutions, but Ecolink offers an incentive that can add a silver lining to replacing AK-225 aerosol acquired in conventional cans. When choosing a replacement solution (FluoSolv CX, for example), users can receive the solvent in aerosol cylinders instead of handheld aerosol cans. Using cylinders instead of cans can offer the following advantages.

- Better price per unit for volume of aerosol

- Less room required for solvent storage (36 pounds of aerosol per cylinder)

- Fewer empty solvent containers (simpler to refill / recycle)

- Refined nozzle control over the solvent stream

- Easy to transport through the facility on two-wheel dolly

Imagine if the aerosol section of your solvent storage area contained compact aerosol cylinders instead of cans. If you use lots of aerosol, you’re looking at a nice increase in floor space thanks to the small footprint of the cylinder compared to the equivalent amount of cans. Plus, remove the need to store cans in multiple locations in large facilities by implementing the cylinder and dolly option. There are lots of reasons to replace AK225 aerosol; our cylinders are one.

Making the Changeover

At a time when eco consciousness has penetrated the industrial sector like never before — a time when the nation, states, and local municipalities pass legislation that regulates or bans toxic substances and practices — companies need a way to make critical solvent replacements, and get on with business, as usual.

That’s what we help you do at Ecolink. Whether cylinders or cans are the right solutions for your solvent spray cleaners, we can provide the AK225 replacement you need, and supply it in the form of scheduled shipments or on an as-needed basis. Save money by purchasing in bulk, or save money by buying on-demand. We serve companies and organizations of all sizes.

Request a Free Sample

To get started on receiving an AK225 aerosol replacement, give us a call today at (800) 563-1305, or use our contact form. Whether a stock product or a custom product is the right option, we’ll send you a free sample to test before you place an order. We look forward to helping your organization improve the safety of its operations with solvent spray cleaners.