What Are Precision Cleaning Solvents?

What are precision cleaning solvents? If you are in a field that has many parts and components that need to be regularly cleaned and degreased, you will want to know. Simply put, precision cleaning solvents are chemical solvents that are versatile and can be used on many different products and surfaces to effectively clean and degrease, without the need for multiple degreasing agents. Precision cleaning solvents make the cleaning process simple and easy, as they provide a degree of one size fits all convenience, without sacrificing quality or effectiveness. The most important decision to make when you are in the market for precision cleaning solvents is deciding on a reliable chemical provider to work with.

You will want to find a supplier like Ecolink to help you customize a high quality, precision cleaning solvent to fit your needs, and ensure maximum effectiveness. Many chemical providers will advertise precision cleaning chemicals, but unless your provider understands your specific needs and customizes a cleaning agent to cater to your business, you are not getting the best solvent for your practice. When you work with Ecolink you will receive necessary customization and a high quality solvent that will effectively clean and degrease.

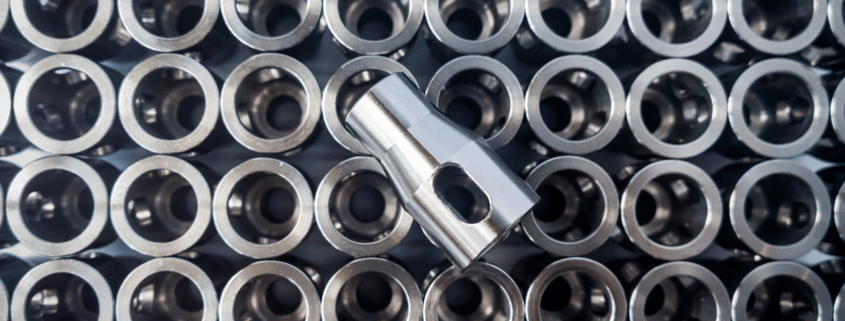

What Are Precision Cleaning Solvents Best Used For?

- Medical Tools

- Industrial Machine Parts

- Electronics Manufacturing

- Watch Manufacturing

- 3D Printing

Shopping for Precision Cleaning Solvents?

All these industries and so many more could benefit from the use of high quality precision cleaning solvents, that the question really becomes, who doesn’t need precision cleaning solvents? If you are interested in learning more about custom precision cleaning solvents, contact us today. Ecolink is a trusted provider of environmentally conscious chemicals and solvents, who will work with you to create the best precision cleaning solvents for your specific needs. Contact us today to get started!