Degreasing Methods: What is Vapor Pressure Cleaning?

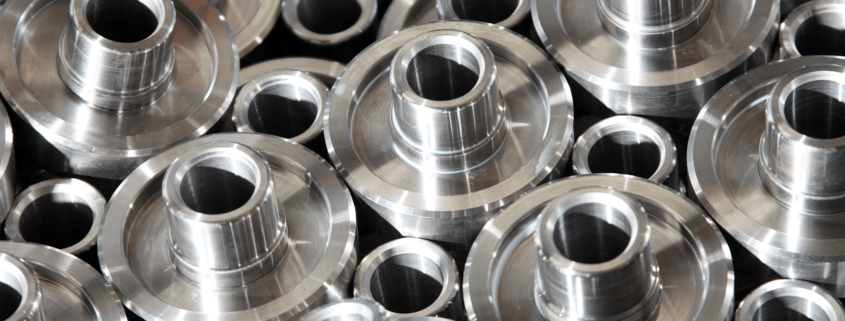

Degreasing is one of the most common industrial cleaning operations. From engine parts to handheld tools, practically every company and organization that uses equipment that accumulates grease must perform degreasing to keep the equipment in ideal condition for its application. One way that this can be done is vapor pressure cleaning — a process in which pressurized vapor from a cleaning agent powers away tough accumulations of grease.

How Vapor Degreasing Works

Unlike degreasing operations that are performed in open air with the use of aerosols, spray liquids, and wipes, vapor degreasing is performed inside a machine that’s specially designed to vaporize a solvent and pressurize the vapor to make it remove grease from parts that are arranged inside the machine. Below is the basic, eight-part process in which vapor pressure cleaning is used to remove heavy grease from parts and leave them looking practically new.

- Work pieces are placed inside the vapor degreasing machine.

- Solvent is placed in a basin inside the machine.

- The machine is closed for the cleaning process.

- The solvent basin’s heating coil vaporizes the solvent.

- The machine builds pressure to make the vapor degrease.

- Solvent drips away from degreased parts, leaving them clean.

- Excess solvent is condensed for recycling or enters a waste trap.

- Parts are removed from the machine and re-implemented.

In some cases, the vapor degreasing process also entails rinsing work pieces in a separate chamber inside the machine to ensure no solvent residue remains, spraying work pieces with a solvent before they enter the machine to speed up the cleaning process, and/or using vacuum degreasers when the machine employs a vacuum to vacuum degreasing system.

Benefits of Vapor Degreasing

Regardless of what comprises the vapor pressure cleaning process, performing it properly can offer several important benefits that help the user execute an efficient cleaning operation, ensure that parts are entirely clean, and curb expenditures for industrial degreasing solvent.

- Eliminates the threat of oxidation and water spots on work pieces

- Prepares parts for finishing processes such as painting and welding

- Cleans precision parts faster than manual cleaning operations

- Offers the opportunity to collect and recycle vapor degreaser

Vapor pressure cleaning is a highly effective method for degreasing precision parts and tools, but two things are always necessary for maximum effectiveness: a parts cleaning machine that facilitates vapor degreasing and using the right type of degreaser for the cleaning process. If you need advice on either requirement, the solvent specialists at Ecolink can help.

Contact Ecolink for Assistance

Vapor degreasing is a simple process that relies on complex machinery and carefully formulated cleaning agents. Because purchasing the vapor pressure cleaning machine and buying solvent is where most of the cost comes in, it is economically imperative to choose the right equipment and cleaner from the start. Using our expertise in parts washing and cleaning solvents, we can help you do this. Just call us today at (800) 563-1305, or use our contact page. We look forward to helping you realize the benefits of vapor degreasing!